Biodegradable bag

Biodegradable composite bag

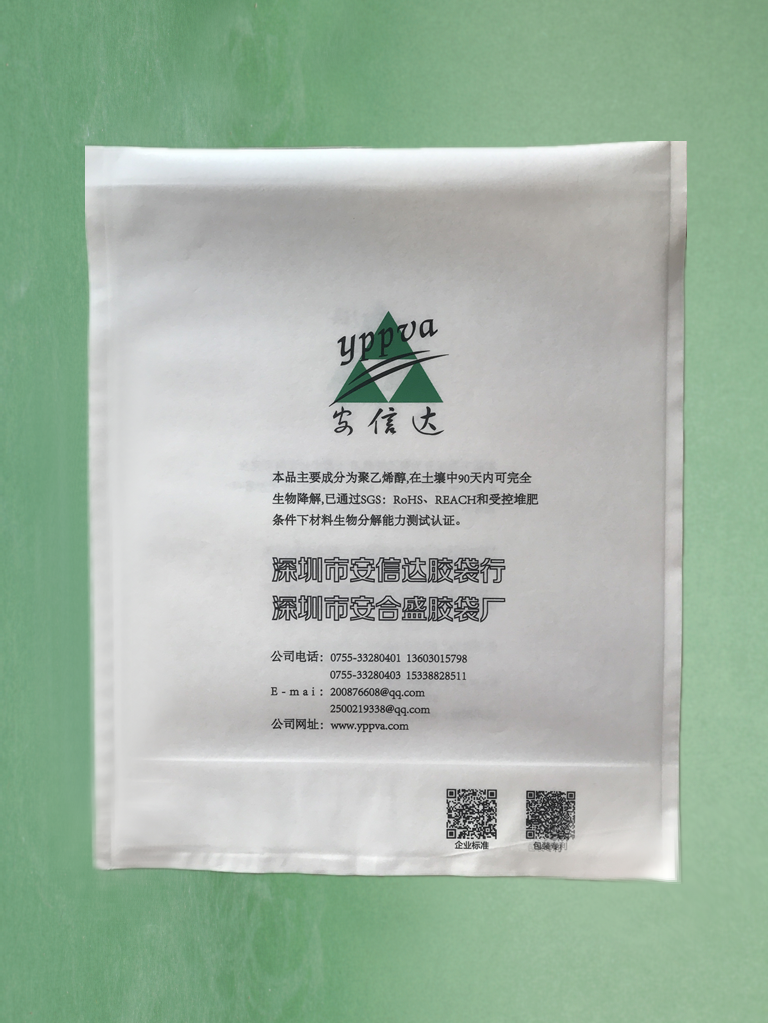

The water-resistant high-temperature high-temperature polyvinyl alcohol film produced by polyvinyl alcohol through wet casting, dry casting, and film blowing processes directly uses the current market laminating machine and papers such as white kraft paper, yellow kraft paper, White card paper and other packaging bags suitable for compounding the outer layer of the inner layer composite film.

Fully utilizes the sealing performance, anti-permeability, heat-sealability, and degradability of polyvinyl alcohol film combined with the printability and decomposition performance of paper. For products with special requirements, more than two layers of composite can be used. Naturally and deeply buried in the soil can be biodegraded and mildewed within 90 days.

The water-resistant high-temperature high-temperature polyvinyl alcohol film produced by polyvinyl alcohol through wet casting, dry casting, and film blowing processes directly uses the current market laminating machine and papers such as white kraft paper, yellow kraft paper, White card paper and other packaging bags suitable for compounding the outer layer of the inner layer composite film.

Fully utilizes the sealing performance, anti-permeability, heat-sealability, and degradability of polyvinyl alcohol film combined with the printability and decomposition performance of paper. For products with special requirements, more than two layers of composite can be used. Naturally and deeply buried in the soil can be biodegraded and mildewed within 90 days.

Product Description

After: Biodegradable bag